highway guardrail jobs

2018-10-13 08:31:21 By:Highway Guardrail Suppliers (1754)

highway guardrail of road construction

As an indispensable part of urban road construction, highway guardrail jobs have become an indisputable fact. Today, we explain the construction methods and techniques of highway anti-collision guardrail in traffic engineering.

highway guardrail jobs talks about the ability to absorb energy of the guardrail. If you haven't seen the guardrail, you can click on the connection of the guardrail. The guardrail is usually a hexagonal hollow tube with a tube thickness of 2 mm. When receiving a huge impact force, the guardrail deformation can effectively absorb the impact force. Accept. We will not introduce the deformation of the column and the ground in detail. The replacement of the guardrail plate is very convenient. It is found that the damaged guardrail plate only needs to remove the bolt, remove the damaged guardrail plate, replace the new bolt, and replace it.

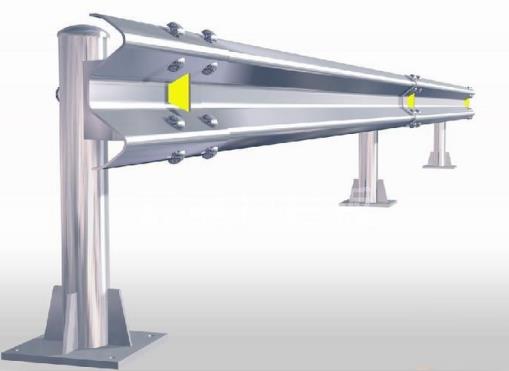

The complete set of accessories of highway waveform guardrail plate include: waveform plate, (flange) column, column cap, connector (block, bracket), bolt, end, transition plate, beam gasket, contour mark, etc. The most common type of wave guardrail is Gr-A-4E. The dosage of each 1000m Gr-A-4E guardrail component is 250 corrugated plates, 250 columns, 250 caps, 250 blocks (or brackets), M16*170 bolts, 250 bolts, M16*42 bolts and 250 bolts. M16*35, 2000 sets. The double wave guardrail plate can be laid in one ton: 3MM thick 80 meters, and 4MM thick 61 meters.

Anti-blocking block is made of Q2 35 material with a thickness of 3 mm. The amount of the product is large, so it is very meaningful to reduce the production cost. Therefore, it is necessary to explore its production process and adopt a more advanced and reasonable process route. Anti-blocking blocks are mainly used between the column and the guardrail. When the car and the guardrail collide with each other, they can reduce the impact force and protect the column and the guardrail. Wave beam guardrail is the main form of semi-steel guardrail. It is a continuous structure with corrugated steel guardrail plates joined together and supported by columns.

2. It uses the deformation of soil foundation, column and beam to absorb collision energy, and force out-of-control vehicles to change direction, return to normal driving direction, prevent vehicles from rushing out of the road, to protect vehicles and passengers, reduce the loss caused by accidents.

3. Wave beam guardrail steel is flexible, has strong ability to absorb collision energy, has better line-of-sight guidance function, can be coordinated with road alignment, beautiful shape, can be used in small radius bends, easy to replace the damage.

Double wave shape guardrail plate: 4320 * 310 * 85 * thickness; thickness: 2.52.75 3.03.85 4.0 three wave shape guardrail plate: 4320 * 506 * 85 * 3/4; waveform guardrail plate surface treatment: hot galvanized, hot galvanized spraying; waveform guardrail double wave column: 11mm * 4.5mm * height; 140 * 4.5mm height; waveform guardrail three wave height: 11. 4 mm 4.5 mm height; 140 mm 4.5 mm height; wavy guardrail generally column spacing is divided into 2 m spacing and 4 m spacing; wavy steel guardrail commonly used models are: Expressway generally used Gr-A-4E and Gr-A-2E class A guardrail, provincial highway generally used Gr-B-4E and Gr-B-2E class B guardrail to protect. Corrugated steel sheet guardrail steel flexible phase can effectively prevent out-of-control vehicles from rushing out of highway accidents, it can use the physical deformation of soil, columns and beams to absorb the energy generated by the collision, and force out-of-control vehicles to change the direction of driving, return to the normal direction of road driving, prevent vehicles from rushing out of the road, to Protect vehicles and passengers and reduce accidents.

Application of highway guardrail

highway guardrail price

Installation of columns (1) the installation of columns should be consistent with the design drawings and coordinate with road alignment. (2) the column should be firmly embedded in the soil to achieve the design level and perpendicular to the road surface. (3) because of the actual situation, it is not possible to use the driving method. All columns shall be constructed with reserved holes or bored piles, and concrete backfill. Accurate positioning should be made during construction. (4) after installing the post, its horizontal and vertical directions should form a smooth alignment. 3. Anti-blocking block installation: Anti-blocking block is fixed to the column by connecting bolts. The bolts between the anti-blocking block and the column should not be tightened prematurely before the installation of the wavy beam. The bolts should be tightened after the guardrail plate is installed in place.

Today's traffic signs can not be as simple as many years ago, the guiding role can meet the requirements of today's urban construction, it is not only beautiful design, enough humanization, but also to reflect the urban culture with the track, then, when you buy traffic signs, you must find a professional production of traffic signs. Factory cooperation, with professional and modern designers, installation personnel, Chuang An Shun has 16 years of traffic sign production experience, in the production strength is strong at the same time more modern design concept, can bring you more creative and better traffic sign products, I believe that this is also what you need.

The driving column is used to set up columns. In order to ensure verticality, a self-made guide should be installed first, and then the column should be inserted along the guide hole. The column should be penetrated into the soil to the design depth. When the penetration is too deep, the part of the column must not be pulled out for correction, but must be pulled out completely until the foundation is compacted and re-penetrated. The installation of columns should be consistent with the design drawings. In coordination with the road alignment, the columns should be firmly embedded in the soil to reach the design depth and be perpendicular to the road surface.

In case of difficulty, the drilled method or excavation method can be used for erection of columns. When using borehole method to install the column, the column should be positioned with the same material as the roadbed backfill, and layered compaction, so that it has no less than the compactness of adjacent undisturbed soil. When the excavation method is adopted and the column is buried, the backfill should be made of the same good material and compacted in layers (the thickness of each layer should not exceed 375 px), and the compactness of the backfill should not be less than that of the adjacent undisturbed soil. Piles in rocks are filled with backfill and tamped.

In view of the impact of highway guardrail jobs on the landscape and the driver's line of sight, the vertical position and elevation should be inspected immediately after the column is installed in place. The verticality inspection uses the ruler to measure the distance between the center line of the road and the column. Elevation check. Verticality is checked by ruler one by one, position is checked, distance is checked by steel ruler, curve section is checked by theodolite, and lateral position is checked by ruler to measure the distance between road center line and column.

The elevation inspection is based on the inner surface of the curb, and is checked by a self-made die or level. Its horizontal direction and vertical direction should form a smooth alignment. The installation of gradual change section and end column should be paid attention to during construction. The position, height and parabola of the column should be strictly controlled during construction. All steel sheets (pipes) must be certified according to the requirements of the design documents. Only experienced receipts can be processed.

Only when the strength of the concrete foundation reaches more than 75% of the design can it be installed. The support is connected to the foundation through the flange. After cleaning the bottom flange and foot bolts, upright the pillar, before tightening the bolts should be adjusted the direction and perpendicularity, and finally tighten the anchor bolts. The cantilever beam can be installed together with the post after assembling the support.

After adjusting the column, the bracket can be installed. The bracket (block) is fixed between the wave beam and the column through the connecting bolt. Before tightening the connecting bolt, the bracket (block) should be adjusted to make it exactly in place. The corrugated beams are joined together by splicing bolts and fixed by connecting bolts on the bracket (anti-blocking block). The overlapping direction of the roadbed guardrail and corrugated beams is the key to installation. The installation is carried out strictly according to the drawings. The direction of lap should be consistent with the direction of traffic. Wave beam should be adjusted continuously during installation. Therefore, the connecting bolts and splicing bolts should not be tightened prematurely in order to make use of the long circular holes of the wavy beam to adjust in time during installation, so as to form a smooth line and avoid local concavity and convexity.

When the alignment of the guardrail is considered satisfactory, the bolt must be tightened at last. The connecting bolts between the bracket (anti-blocking block) and the wavy beam should not be screwed too tightly so as to adjust the temperature stress by using the long round hole. The end beam is spliced with the standard guardrail through splicing bolts. The construction method of the end beam is basically the same as that of the wavy beam. After the section construction is completed, the self-inspection is qualified and the supervision engineer is submitted for acceptance.

-

Related News:

- highway guardrail forming machine

- galvanized highway guardrail for sale

- highway guardrail llc nc

- used highway guardrail prices

- w beam highway guardrail for sale

- highway guardrail bolts