highway guardrail manufacturers india

2018-10-18 19:52:03 By:Highway Guardrail Suppliers (1793)

highway guardrail manufacturers india

ICRA, India's credit rating agency, says highway guardrail manufacturers india may face short-term profit pressures, even if raw materials have eased.

Market and its application: Fence can be seen everywhere in the street, road, railway, even school playground and other places have to set up a fence. This is for safety reasons, and also for aesthetic considerations. Do you know how the fence is made, and what kinds of uses are there? The following are related introductions. Fence material: low carbon steel wire, aluminum magnesium alloy wire.

Fence weaving and characteristics: weaving and welding. Types of fence net: highway fence net, municipal fence net, railway protection net, stadium fence net, hook net, gill rope series fence net use: used for highway, railway, airport, residential district, port, wharf, garden, feeding, animal husbandry and other fence protection.

Features of the fence products are anti-corrosion, anti-aging, anti sun and weather resistance. The forms of anticorrosion are electroplating, hot plating, spray molding and dipping. Guardrail is used to protect order, but in the premise of achieving protection also pay attention to aesthetics, so the choice of guardrail should be based on the use of choice, but also to choose advanced technology companies to do.

The display performance of the guardrail is particularly prominent, reflecting its main role is to ensure our safety. The most important feature we can understand from the safety point of view is the installation of more important guardrail, not only in the level of application we can see some results, we can also have more aspects. A small one.

What steps should be paid attention to when installing the guardrail plate of corrugated beam? 1. Before construction preparation, the construction technicians should be familiar with and understand the design drawings and related construction specifications.

They should go to the construction site and check the design drawings one by one with the construction personnel to find out the pile numbers, various structures and structures of the construction section. The location of guardrail should be set up, and the construction equipment and material entry work should be done well.

2. Waveform guardrail lofting, column should be lofting according to the design drawings, and bridges, passages, culverts, interchanges, level crossings and other control points, ranging and positioning, can be used to adjust the interval, and use the allocation method to deal with the number of spacing zero.

2. To accurately loft and ensure the alignment of the guardrail, pile number is checked and closed. (3) After the pillars are laid out, the surface state of each pillar position should be investigated, such as underground communication pipeline, water leakage, etc., or when the depth of burial at the top of culvert is insufficient, the position of some pillars should be adjusted and the fixing method of the pillars should be changed. Anti-blocking block is made of Q2 35 material with a thickness of 3 mm. The amount of the product is large, so it is very meaningful to reduce the production cost.

Therefore, it is necessary to explore its production process and adopt a more advanced and reasonable process route. Anti-blocking blocks are mainly used between the column and the guardrail.

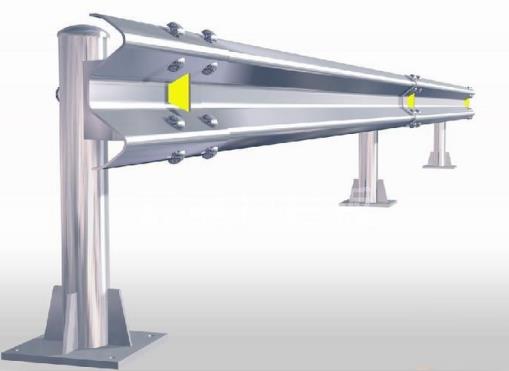

When the car and the guardrail collide with each other, they can reduce the impact force and protect the column and the guardrail. Wave beam guardrail is the main form of semi-steel guardrail. It is a continuous structure with corrugated steel guardrail plates joined together and supported by columns.

2. It uses the deformation of soil foundation, column and beam to absorb collision energy, and force out-of-control vehicles to change direction, return to normal driving direction, prevent vehicles from rushing out of the road, to protect vehicles and passengers, reduce the loss caused by accidents.

Corrugated beam guardrail steel is flexible, has strong ability to absorb collision energy, has better line-of-sight guidance function, can coordinate with road alignment, beautiful shape, can be used in small radius bends, easy to replace the damaged guardrail manufacturers many people suspect that a group of simple guardrail plate can really be effective Slow down the impact of the vehicle and force the vehicle to stop.

The guardrail plate is semi steel. When a group of guardrails is spliced together, it is supported by columns. When receiving strong external impact force, force the ground, pillars, blocks, wave fence deformation to absorb energy, in which the deformation of each component can absorb strong energy.

Semi-steel guardrail plate has greater cushioning capacity, better absorptive capacity, and will not break even if it receives greater impact force. Installation of columns

(1) the installation of columns should be consistent with the design drawings and coordinate with road alignment.

(2) the column should be firmly embedded in the soil to achieve the design level and perpendicular to the road surface.

(3) because of the actual situation, it is not possible to use the driving method. All columns shall be constructed with reserved holes or bored piles, and concrete backfill. Accurate positioning should be made during construction. (4) after installing the post, its horizontal and vertical directions should form a smooth alignment.

3. Anti-blocking block installation: Anti-blocking block is fixed to the column by connecting bolts. The bolts between the anti-blocking block and the column should not be tightened prematurely before the installation of the wavy beam. The bolts should be tightened after the guardrail plate is installed in place.

Application of highway guardrail

highway guardrail manufacturers india

Rusty guardrails should also be cleaned up promptly and classified. Because it belongs to the common high-speed enclosure construction material, after professional recycling and degradation treatment, it still has a wider scope of application.

The surface of the highway guardrail is galvanized and electroplated, and the main material is oxide paint. In the production process of highway guardrail, it will be evenly coated with a layer of anti-corrosion equipment, more conducive to improving the anti-corrosion effect of highway guardrail.

Finally, in order to solve the daily anti-corrosion of highway guardrail, regular maintenance is one of the indispensable links, the use of regular maintenance, long distance from the road guardrail products, professional separation, road maintenance and construction personnel, in the process of regular inspection of highway, more attention should be paid to both sides of the guardrail is Whether there is any damage, welding or serious corrosion, such problems should be promptly notified to the highway management center, so that they send professional maintenance personnel to carry out on-site cleaning, replacement or other aspects of maintenance work. When installing the wavy beam and the wavy beam, the splicing bolts are joined to each other, and the connecting bolts are fixed on the column or beam.

The direction of wave beam splicing is the key to installation. During construction, the lap direction should be consistent with the direction of traffic. (2) The wavy beam should be adjusted continuously during installation, so the connecting bolts and splicing bolts should not be tightened too early, so that the long circular holes of the wavy beam can be adjusted in time during installation to form a smooth line and avoid local concavity and convexity. 3. When installing, the top surface of the corrugated beam should be coordinated with the vertical curve of the road. And check the alignment of the guardrail. When the alignment is straight and smooth, the bolt can finally be tightened.

Concrete foundation Gr-SB-4E roadside SB-class double wave beam guardrail, column spacing 4m, penetrating Gr-SB-2E roadside SB-class double wave beam guardrail, column spacing 2m, penetrating Gr-A-2B1 roadside A-class double wave beam guardrail, column spacing 2m, pre-embedded sleeve Gr-SB-1B1 roadside SB-class three wave beam guardrail, column spacing 1m.

Barrel type Gr-Am-4E segregating belt separated Am class double wave beam guardrail, column spacing 4m, penetrating type Gr-Am-2E segregating belt separated Am class double wave beam guardrail, column spacing 2m, penetrating type Gr-SBm-1B1 segregating belt separated type SBm class three wave beam guardrail, column spacing 1m, pre-embedded sleeve type Grd-Am-2E segregating belt combined type double wave beam guardrail Waveform beam guardrail, column spacing 2m.

Important Grd-Am-1B1 partition with combined Am-class double wave beam guardrail, column spacing 1m, embedded sleeve type this is a variety of waveform guardrail specifications, according to the anti-collision grade can be divided into A and S. The S grade guardrail is an enhanced type. It is suitable for road sections which are especially dangerous. There is also a general B multi-purpose and county road.

Two wave shape guardrail board: 4320 * 310 * 85 * 3 / 4mm; three wave shape guardrail board: 4320 * 506 * 85 * 4mm two wave guardrail board column: 114 / 140 mm * 4.5mm * height; three wave guardrail board column: 130 * 130mm * 6mm * height; guardrail board is generally divided into five colors: galvanized silver white, spray green, white, blue and so on. According to the waveform, it can be divided into two wave guardrails and three wave guardrails.

According to surface treatment, it can be divided into two types: galvanized wave guard rail and galvanized spray molding. According to the location, they can be divided into roadside guardrails and divider guardrails. Highway wave guardrail plates can be divided into class A and S according to the level of collision avoidance. The S grade guardrail is an enhanced type. It is suitable for road sections which are especially dangerous. Commonly used roadside wave beam guardrail can be divided into five levels, B, A, SB, SA and SS according to the level of collision avoidance.

-

Related News:

- highway guardrail systems used

- w beam highway guardrail cost in china

- thrie beam guardrail manufacturer australia

- galvanized highway guardrail

- highway guardrail weight per foot

- a highway guardrail is designed