highway guardrail manufacturers usa

2018-10-26 18:43:19 By:Highway Guardrail Suppliers (3223)

highway guardrail manufacturers usa introduce

In the 1960s and 1970s, the highway guardrail manufacturers usa began to optimize the end of the guardrail, and eventually formed the "NCHRP 350 Report" in 1993, and has been used so far. At present, the United States through the "NCHRP 350 Report" guardrail terminal form mainly has three designs: energy absorption, outward, embedded.

The energy-absorbing end design includes two types: the displacement type of the end and the disintegration type of the end. The displacement type of the end eliminates the kinetic energy of the collision between the vehicle and the end by the displacement of the end. The disintegration type of the end of the guardrail disintegrates with the column when the collision occurs, so as to absorb the kinetic energy of the collision.

Embedded end design: The end of guardrail is buried in the side slope protection to realize the redirection of out-of-control vehicles. This form requires suitable terrain, for example, both sides of the slope, if there is no slope, can use engineering means to "manufacture" slope protection.

Outward-looking end design: the end to the side of the road safety clearance deflected a certain distance to prevent the end of the guardrail through the body.

Application of highway guardrail

Traffic accidents often involve many factors such as people, vehicles, roads and so on. We can not completely eliminate vehicle failures, nor can we completely prevent people from making driving mistakes, at this time, "friendly" roads and road facilities to mitigate the consequences of accidents, to save lives is essential.

Because the application of highway guardrail is very extensive, we will use it many times. So what should we pay attention to when choosing the highway guardrail? The following are the manufacturers of highway guardrails we introduced. According to the introduction of highway fence manufacturers, attention should be paid when choosing highway guardrail. Column quality and frame of the highway guardrail, guardrail columns and frames are also lower than one place, some conventional large factories use angle steel, round steel, but angle steel, round steel in different parts should be different.

Generally speaking, attention should be paid to the uniformity of sprayed plastics and the quality of coatings. Thirdly, it is the advanced level of management and equipment for spray technology.

highway guardrail manufacturers usa address

The quality of highway guardrail is welded by different sizes of wires. The diameter and strength of wire directly affect the quality of mesh. In the selection of wire, should be the regular manufacturer of finished wire, the next is wire mesh welding or preparation. This is mainly watching technology. Skilled operation skills and good production equipment.

Usually a good mesh is connected to each welding point or preparation point. Some of Anping's conventional fence factories are manufactured by automatic welding machines, while a small factory is manually welded, and the quality is often difficult to guarantee.

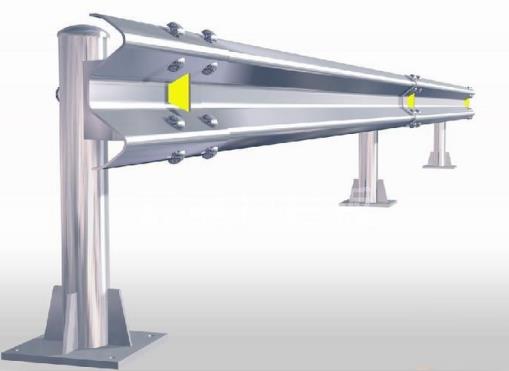

The highway guardrail is made of zinc alloy steel. It is strong and durable. It is not easy to rust. The surface is treated by electrostatic spraying and high temperature paint. It has the characteristics of high temperature resistance, rain resistance, sunshine resistance, corrosion resistance, not easy to fall off, and has become a park, a residential area, a garden factory, a villa, a highway, a balcony priority products. Next we will introduce the production process of highway guardrail.

The zinc alloy steel tubes are cut into small segments according to the specifications and sizes required by customers. Zinc steel guardrail beams, vertical bars, columns, pipe type, size are different, different section according to different specifications sawing. Good beams are welded according to the distance between the vertical bar and the vertical bar, and the columns are welded after the grid is welded.

First of all, it is very good to weld the riser on the column, and the expansion screw can be used to impact the column. In the welding connection of zinc steel guardrail beam, the bottom plate is welded at the bottom of the column, and the welding technology of zinc steel guardrail is well done. Then, electrostatic spraying and high temperature baking technology are applied to powder spray welding of zinc steel guardrail.

Generally, the zinc steel municipal road guardrail is mostly white, because its surface is also covered with a reflective band, as well as traffic signs, reflective band using optical principle, can be reflected back to a special structure of composite light source. In this way, in the night light, it can reflect a clear light, so that drivers or other people can see the safety warning, and banning signs is increasingly important for traffic safety.

-

Related News:

- road guardrails suppliers near me

- highway guardrail systems

- w beam highway guardrail cost in china

- highway guardrail suppliers in malaysia

- highway guardrail corral

- galvanized highway guardrail