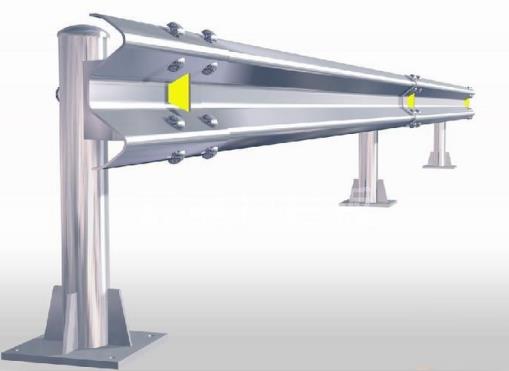

highway guardrail nj

2019-07-03 08:19:34 By:Highway Guardrail Suppliers (2568)

highway guardrail nj character

highway guardrail nj was developed by the Stevens Institute of Technology in Hoboken, New Jersey, to separate highway lanes. They designed the highway guardrail nj, which is about 90 to 150 centimeters high, made of grouted concrete and weighs up to 1,000 kilograms.

highway guardrail nj is a kind of wall guardrail with a certain section shape. Its characteristics are: when the car collides with the guardrail, the guardrail basically does not move and deform (rigid state) under the action of instantaneous moving load.

The energy during the collision mainly depends on the contact between the car and the guardrail to climb along the guardrail surface. And turn to absorb.

At the same time, the collision car also returned to normal direction. Generally speaking, the highway guardrail nj is more advantageous to the climbing and steering of the collision vehicle, so it is better to reduce the damage of the vehicle and protect the safety of the passengers on the vehicle, but it is easy for the high-speed heavy vehicle to cross the barrier and rush to the opposite lane or out of the road.

highway guardrail nj can be installed after the completion of the pavement foundation. Greatly shorten the construction period and facilitate operation.

highway guardrail nj without sleeper beams during the installation process, without prefabrication of sleeper beams, thereby reducing the cost.

highway guardrail nj under small gap can be directly with mortar, no cast-in-place small stone concrete, reduce costs.

Our Chinese manufacturer's highway guardrail is much cheaper than the highway guardrail nj, and the structure is stable, can play a very good role in traffic protection, welcome to inquiry.

highway guardrail nj appearance quality problems

highway guardrail appearance quality problems are manifested in the following aspects: 1) the surface is not glossy, not smooth; 2) the edges and corners fall off; 3) bubble; 4) sand line; 6) honeycomb hemp surface; 9) rotten roots.

Formwork quality: Although the use of wood formwork construction can increase the permeability of concrete pouring process, facilitate the discharge of concrete bubbles, but because of the surface roughness of the finished product surface gloss and smoothness, it is abandoned.

Steel formwork can increase the surface smoothness and gloss of concrete, but it is not conducive to the discharge of bubbles, so increase the side formwork to the device.

The surface cleanliness of steel formwork has a direct impact on the appearance of concrete, and because of the long use time, easy deformation, formwork cracks are easy to become larger, so it is determined as the main reason.

Demoulding agent: The use of demoulding agent has a direct impact on the appearance of concrete and the difficulty of demoulding.

Formwork support cubic formula: according to experience, the positive slope formwork is conducive to the discharge of bubbles, the reverse slope formwork is not conducive to the discharge of bubbles, because the trial formwork upside down support pouring, so the transformation of a set of formwork upside down support and pouring, compared with the vertical formwork pouring products to determine whether the main reason.

Concrete slump: concrete slump is an important factor affecting the quality of concrete, not only affects the strength of concrete, but also has an inseparable relationship with the appearance of concrete quality, determined as the main reason.

Application of highway guardrail

Vibration technology: To investigate the finished products and determine the vibration technology.

-

Related News:

- road guardrails price

- w beam guardrail post spacing china

- highway guardrail components

- highway guardrail nj

- road guardrail manufacturers of bridge

- galvanized highway guardrail