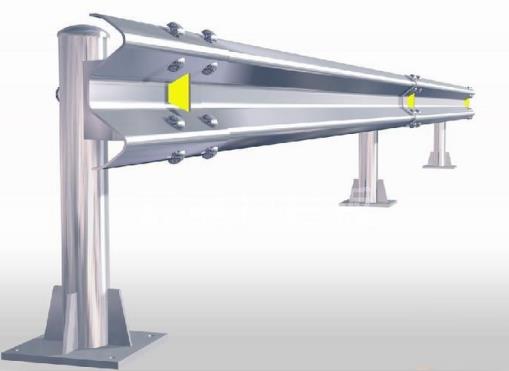

steel road guard rails for sale

2019-11-22 09:55:33 By:Highway Guardrail Suppliers (2424)

steel road guard rails for sale analysis

steel road guard rails for sale is very fierce. With the increase of raw material price, every manufacturer is calculating how to control cost reasonably.

Coarseness of galvanized surface: When too much iron-zinc alloy is formed or unevenly distributed, it will cause surface roughness. And the surface may appear a little white rust, white rust guardrail will make people feel serious corrosion, which is not the white powder zinc rust layer, just after wiping after weak acid treatment.

steel road guard rails for sale kind of white rust is due to its high stability, which causes the formation of iron-zinc alloy heart element, and the longer galvanizing time, which increases the diffusion reaction of iron and zinc. 2. When galvanized guardrail plate is galvanized, if the residual water contains chloride, sulphide in industrial environment or zinc content in galvanizing is too high

it is necessary to replace galvanizing bath or cool down treatment, and salvage zinc slag, so as to prevent zinc particles from being too dense. However, due to the steel road guard rails for sale hot-dip galvanizing process and cost control, the existence of a small amount of zinc particles is inevitable.

Application of highway guardrail

Caking and zinc nodules, flow marks: Excessive pickling results in uneven distribution of elements in the steel matrix, resulting in rough surface due to different dissolution rates or microbattery action during pickling.

steel road guard rails for saleabove is due to the roughness of the galvanized layer caused by the process, which can be improved by adjusting the process. Because the surface of the selected steel is rough and uneven, with rust or obvious rolling stripes, the surface will still be rough after galvanizing.

influenced by the composition of steel, when the carbon element exceeds 0.2%, phosphorus exceeds 0.5%, manganese exceeds 13%, the galvanizing layer formed is different from the normal galvanizing layer. In these cases, the galvanizing process can only achieve limited control. 4. Scratches: Scratches inevitably occur in the process of transportation and loading and unloading of guardrail materials.

From the characteristics of hot-dip galvanizing, we can know that the color difference between zinc and iron is obvious. However, the anodic protection of zinc layer can protect the surface from slight scratches. Zinc-rich paint can be used to treat scratches steel road guard rails for sale.

steel road guard rails for sale development

Bubbles in galvanized layer are caused by excessive pickling before galvanizing or insufficient inhibitors added in the acid solution, resulting in more hydrogen adsorbed on the surface of steel parts during pickling, and no drying water and degassing before entering the galvanizing pot.

steel road guard rails for sale by steel is discharged during solidification of galvanized solution to form bubbles. The existence of a large number of bubbles makes the zinc coating loose and not compact. Under the environment of high temperature, rainwater and humidity, the zinc coating oxidizes into white rust, which produces zinc oxide, zinc hydroxide and zinc carbonate corrosion products, i.e. white ash on the surface of highway guardrail.

trinity highway guardrail lawsuit

The galvanized layer oxidized to white ash steel road guard rails for sale, and the zinc layer thinned, so that steel road guard rails for sale could not pass the collapsing test of copper sulfate solution. Article 5.1 of American Standard Specification 6MA153 for Hot Dip Galvanizing of Iron and Steel Parts (re-approved in 1987) clearly stipulates that "galvanized parts shall not have uncoated parts, bubbles (Blisters).

flux deposits, black spots, solvent inclusions and various types of projections that hinder the expected use of galvanized parts, or other defects incompatible with good galvanizing operations." The surface quality requirement of galvanized layer in the standard J81 of expressway guardrail board should be free from defects such as leak plating and exposed iron, and there is no explicit regulation for air bubbles.

The surface of the freeway guardrail plate installed on the expressway turns white and rusty to grey and white because of the bubble of the coating, which can not meet the requirement of "uniform and complete.

steel road guard rails for sale of the technical standard coatings, and has not been used in traffic. The galvanized layer of the freeway guardrail plate has been thinned to unqualified because of the white rust. Therefore, the freeway guardrail plate installed on the freeway with a large number of bubbles should be removed, dezincified and re-plated.

-

Related News:

- highway guardrail roll forming machine

- w beam highway guardrail for sale

- highway guardrail suppliers in georgia

- highway guardrail forming machine

- highway guardrail nj

- The safety function of highway guardral for automobile running