w beam guardrail cost per foot

2020-01-26 13:48:33 By:Highway Guardrail Suppliers (2509)

factors influencing of w beam guardrail cost per foot

the factors influencing of w beam guardrail cost per foot are raw materials, surface anti-corrosion processing, sales cost, seasonal requirements and market.

On the highway, when the highway belt is used, the role of the guardrail can cut off two roads, playing a very good role in separating, but also can play a role of protection.

And after using the waveform fence, it will be safer. For example, if a car accidentally bumps into it, w beam guardrail cost per foot will not be easy for the car to crash, and the most important thing is to protect the personal safety of the driver and passengers in the car. These are very important things, so we must not underestimate the role of the waveform fence.

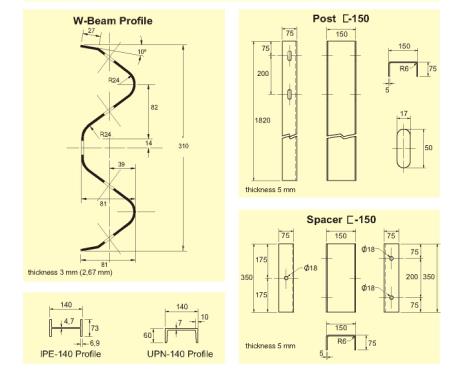

w beam guardrail cost per foot the raw materials of waveform guardrail of expressway are Q195, low carbon steel plate, etc.Surface treatment methods: dipping after extrusion forming, or dipping or spraying after stamping of galvanized/hot galvanized steel sheet;

After extrusion, dipping of low carbon steel blackboard; after extrusion, galvanizing + dipping / spraying of low carbon steel blackboard; the dipping material is (pvc & pe);Scope of application: Safe collision avoidance of expressway w beam guardrail cost per foot, large parking lot, etc.

w beam guardrail cost per foot.Product features: bending increases the aesthetics, while increasing the strength of the mesh, both; extrusion forming of automatic production line, surface neatness, non-damage, anti-corrosion is very strong; surface treatment is mature; PE & PVC material has non-toxic and harmless, anti-corrosion.

anti-aging, anti-sun, high resistance, low temperature and other characteristics, the service life of outdoor environment can reach 10-20 years; product structure is concise, beautiful and practical. Easy to transport and install, good anti-theft performance, limited by the actual terrain, strong adaptability to mountainous, sloping and multi-bend areas, moderate cost, suitable for large-scale use.

w beam guardrail cost per foot introduce

Semi-rigid waveform guardrail has been widely used in highway safety facilities for w beam guardrail cost per foot advantages of large resistance, long service life, convenient installation and maintenance.

w beam guardrail cost per foot raw materials are steel highway guardrails, steel materials are easy to oxidize and rust in the air, so what is the specific function of the guardrail in various harsh environments for decades of color-invariant rust? What is the surface anti-corrosion of corrugated guardrails?Corrosion treatment of corrugated guardrail surface generally includes hot-dip galvanizing, spraying, hot-dip galvanizing + spraying three methods!

Hot-dip galvanized corrugated guardrail.Hot-dip galvanizing metal materials immersed in zinc solution after cleaning about 500 degrees, so w beam guardrail cost per foot the metal surface, to achieve the purpose of corrosion protection, hot-dip galvanizing has developed to today more than 100 years of history, technology is relatively mature, highway guardrail plate processing technology used.

used highway guardrail for sale nebraska

The powder is sprayed onto the workpiece by electrostatic spraying equipment. Under the action of electrostatic force, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating.

w beam guardrail cost per foot after baking at high temperature, the coating is smooth and solidified. Form a sprayed surface.Hot-dip galvanizing and plastic coating process is hot-dip galvanizing and then spraying. This effect is better than the first two anti-corrosion effects, of course, the cost is high!

-

Related News:

- highway guardrail llc

- highway guardrail end caps

- crash barrier or guardrail in china

- thrie beam guardrail price weight per foot

- highway guardrail strength

- highway guardrail corral