w beam guardrail post spacing china

2020-05-06 17:33:44 By:Highway Guardrail Suppliers (2038)

w beam guardrail post spacing china description

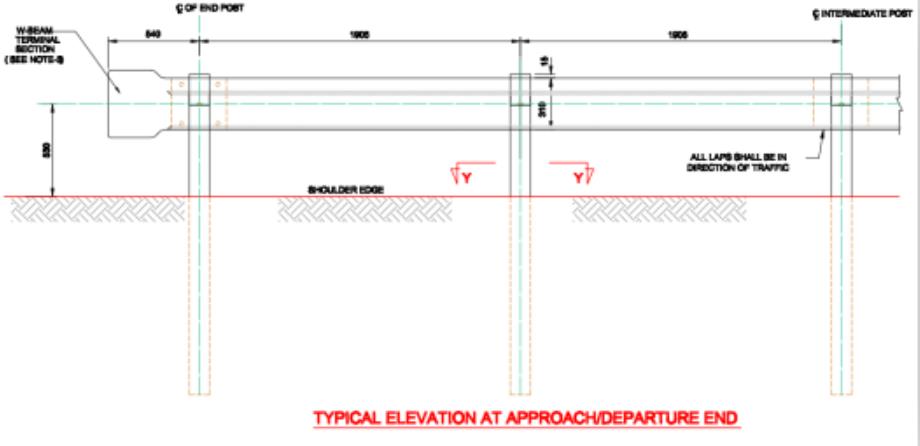

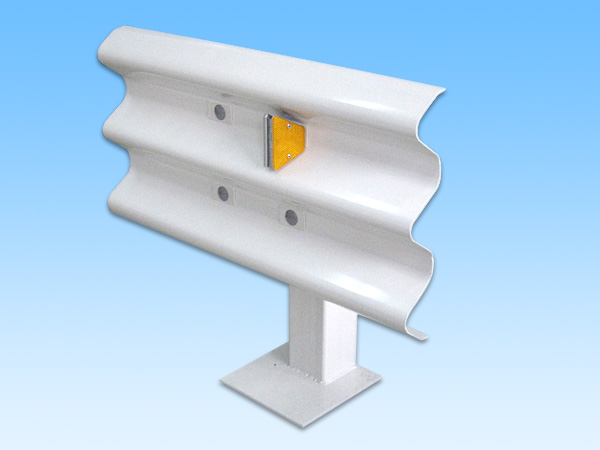

w beam guardrail post spacing china is the distance from the center point of column installation to the center point. The setting location can be divided into roadside guardrail and median guardrail.

The hot-dip galvanizing process is to immerse the workpiece in the high-temperature molten zinc solution, so that the external surface of the workpiece is attached with a zinc layer.

The finished product is pickled, washed, added with auxiliary plating solution, dried, hung plating, cooled, medicated, cleaned, polished, hot-dip galvanized, and completed. The guardrail with the whole process completed has better anti-corrosion and anti rust functions.

What is the effect of galvanizing process on corrugated guardrail?In suburban environment, the standard thickness of hot-dip galvanizing can be maintained for more than 50 years without repair; in urban or offshore area, the standard thickness of hot-dip galvanizing antirust layer can be maintained for 20 years without repair.

The galvanizing layer is metallurgical combined with the steel and becomes a part of the steel surface, so the durability of the coating is more reliable.Zinc coating constitutes a special metallurgical structure, which can withstand the mechanical damage during transportation and use.

w beam guardrail post spacing china every part of the plated part can be zinc plated, even in the depression, sharp corner w beam guardrail post spacing china and hidden place can be fully maintained. The galvanizing process is more convenient than other coating construction methods, and can prevent the time required for painting on the site after installation.

In general, the cost of hot-dip galvanizing is lower than that of other maintenance coatings. The reason is simple. Other maintenance coatings, such as sanding paint, are labor-intensive processes.

w beam guardrail post spacing china on the contrary, the process w beam guardrail post spacing china of hot-dip galvanizing is highly mechanized and closely controlled in plant construction. The hot-dip galvanized layer can be tested by visual and simple non-destructive coating thickness table. The hot galvanizing process of corrugated guardrail has many advantages.

w beam guardrail post spacing china rule

w beam guardrail post spacing china some points need to be paid attention to in the production process of corrugated guardrail board.

During production and processing, setting out shall be carried out first to make the formwork. The formwork shall be produced in strict accordance with the requirements of customers.

w beam guardrail post spacing china is necessary to do a good job in galvanizing and anti-corrosion treatment of corrugated guardrail. The guardrail is galvanized in high-temperature galvanizing furnace, and the temperature of galvanizing furnace should not be too high or too low, which needs strict control, otherwise w beam guardrail post spacing china will directly affect the anti-corrosion effect.

Spray plastic treatment is also strict, some manufacturers produced spray plastic guardrail board uneven, spray plastic effect is not good. This is because the spray equipment of the guardrail is not good. The spray equipment is all assembly line operation. The good spray equipment sprays out the guardrail board, and the surface is very even.

Guardrail board is an important part of the highway. The reuse of the used guardrail board reflects the w beam guardrail post spacing china sustainable development strategy and the improvement of people's environmental awareness in recent years.

The surface treatment of corrugated guardrail is directly related to its service life and function. In the development of many years, the guardrail is considered from single anti-corrosion function to beautiful, environmental protection and other aspects. The surface treatment of guardrail constructed in the early stage in China is mainly hot-dip galvanizing.

w beam guardrail post spacing china has been used for many times in similar projects at home and abroad because of its excellent anti-corrosion effect and economy.

-

Related News:

- highway guardrail cost per foot

- steel roadside guardrails for sale

- highway guardrail strength

- highway guardrail products

- crash barrier suppliers near me

- w-beam highway guardrail